Deep Neural Network Nonlinear Model Predictive Control for CSTR#

Introduction#

The Continuous Stirred Tank Reactor (CSTR) is a fundamental model in chemical engineering, representing a reactor where the contents are well-mixed, ensuring uniform composition and temperature throughout. This report delves into the mathematical modeling of a CSTR, its simulation, and control using a Nonlinear Model Predictive Control (NMPC) strategy integrated with a neural network for predictive behavior.

CSTR Model#

The CSTR dynamics are governed by the mass and energy balance equations:

The reaction rate is:

Parameter |

Value Description |

|---|---|

Initial Flow Rate |

Initial volumetric flow rate |

Initial Temperature |

Initial temperature |

Initial Concentration |

Initial concentration |

Reactor Radius |

Reactor radius |

Reaction Rate Constant |

Reaction rate constant |

Activation Energy/Gas Const |

Activation energy/gas constant |

Heat Transfer Coefficient |

Overall heat transfer coefficient |

Density |

Density |

Specific Heat Capacity |

Specific heat capacity |

Heat of Reaction |

Heat of reaction |

Small Value |

Small value |

Mass Fractions |

Mass fractions |

Input Parameters |

Input parameters |

Parameter Equations#

Nonlinear Model Predictive Control (NMPC)#

NMPC optimizes control inputs over a prediction horizon to minimize deviations from desired setpoints while respecting constraints.

Parameters#

Cost Function#

Where:

Weights:

Constraints#

ACADOS Configuration#

Solver: SQP / SQP-RTI

Integrator: IRK

QP Solver: PARTIAL_CONDENSING_HPIPM

Condensing: Full (\(N\) intervals)

Regularization:

Neural Network Integration#

Data Preparation#

Gather time-series data: concentration, temperature, inflow, heat input

Scale input/output:

Neural Network Architecture#

Input: \( \mathbf{a}_0 = \mathbf{x} \)

Hidden layers:

Output:

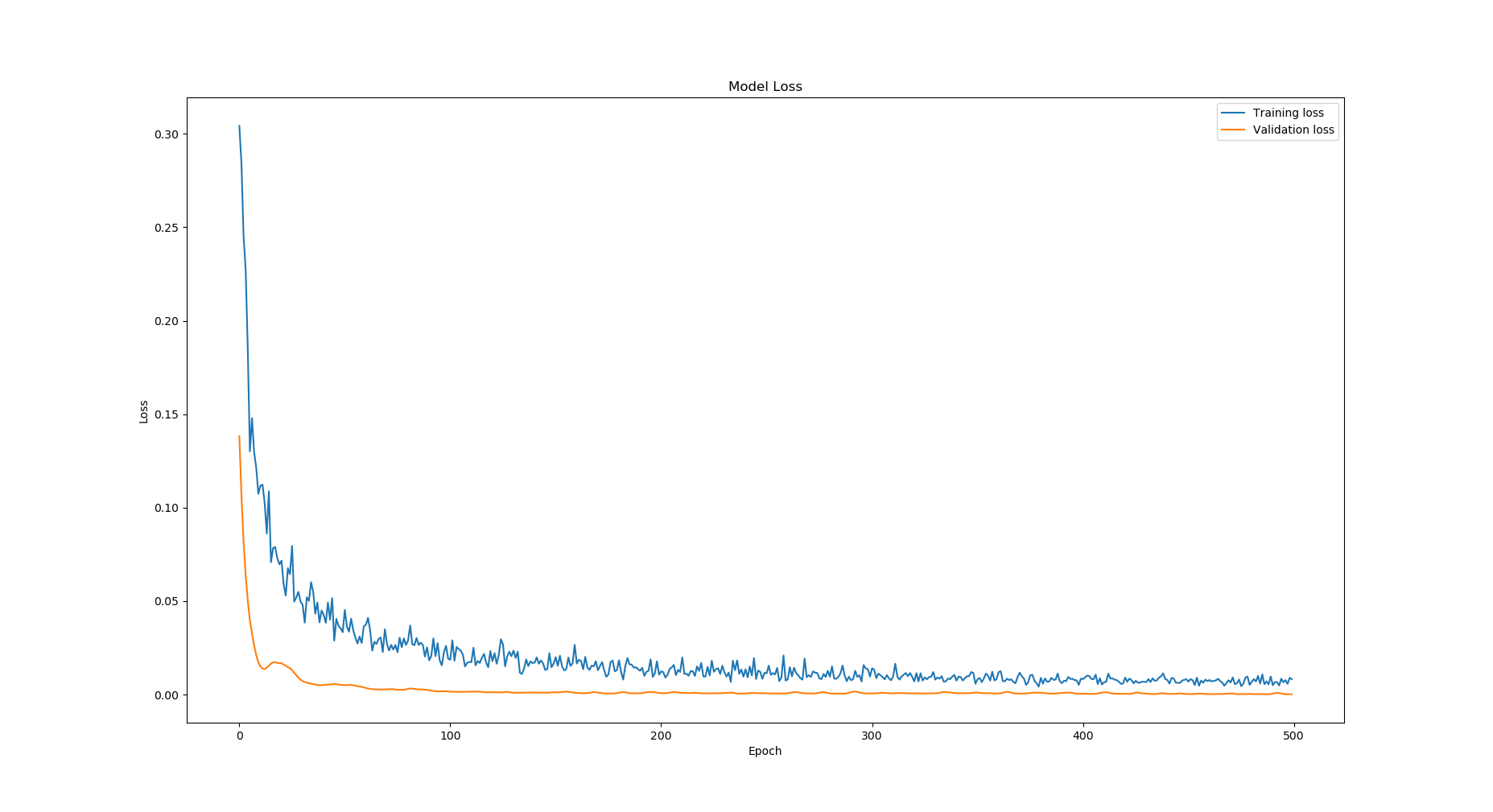

Training#

Loss: Mean Squared Error

Optimizer: Adam or SGD

Validation: Prevent overfitting using a held-out validation set.

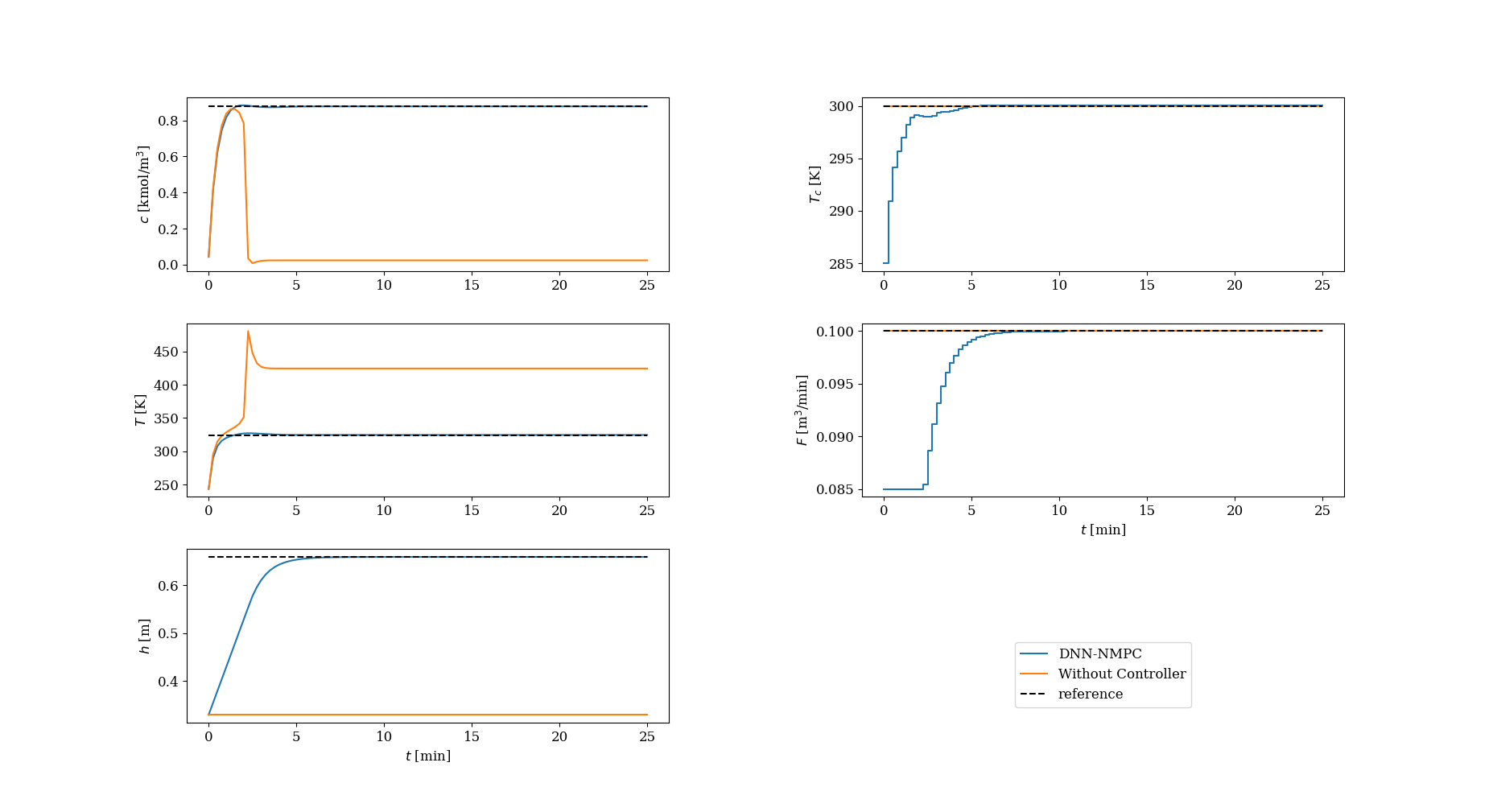

Results#

Conclusion#

The CSTR model, integrated with a neural network and controlled via NMPC, represents a sophisticated and powerful approach for managing complex chemical systems. This architecture allows for efficient real-time control and adaptation to dynamic operating conditions.